.jpg)

We offer a quality range of fume exhaust line that is designed essentially for commercial as well residential kitchens. Fabricated using the best quality raw material, these systems require less maintenance and have long working life. The design is customized as per specific requirement of customers. We also provide complete installation services for these systems.

We offer an exclusive range of Industrial Air Ventilation System that are useful in providing clean and safe environment in various production and warehouse units. These are manufactured using high quality raw metal and other instruments that meet international quality standards. These are widely demanded due to high durability, excellent performance, dimensional accuracy, corrosion abrasion and toughness.

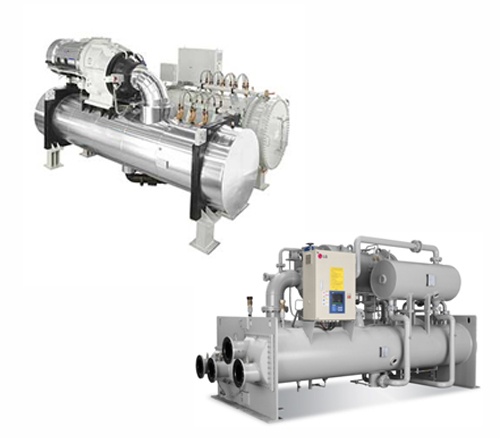

Technocon Water-cooled Screw Chillers, Centrifugal Chiller, Liquid Chiller, Water Chiller, Water Cooled Chiller are designed to work within extreme tropicalized weather conditions, while maintaining the highest energy efficiency. Designing and the choice of equipment are critical to conform to superior standards. Manufacturing and testing at our facilities confirms to international standards and are at par with the best. Installed equipments are operation friendly and are backed by competent engineering team to realize the advantage while being in operation.

Technocon centrifugal chillers are highly energy efficient and are equipped with the new generation centrifugal compressors with magnetic bearings. These two-stage compressors, coupled with the in-built Variable Speed Drives, enable significant reduction in the operating cost as well as reduce emissions. The centrifugal chillers offer highest sustainable efficiency with low maintenance and are ideal for data centres, hospitals, hotels, green buildings, educational institutions, as well as industrial and process applications.

Technocon water cooled mini ducted units of 1.5 TR, 2.0 TR and 2.5 TR are unitary air conditioning with compact closed refrigerant circuit. In this compact system, compressor, evaporator, shell and tube condensers and all accessories are mounted in a single insulated cabinet. The machines come with high efficiency rotary compressors and maintenance-friendly shell and tube water cooled condensers. Minimum refrigerant piping length improves the efficiency. The compact size of the machines and low noise fans make it an ideal choice for commercial complex, hotel rooms, industrial air conditioning, cement plants and malls where there are advantages of better energy efficiency and individual control. The installation is fast and simpler as requires only water pipe connections and minor ducting at site.

Ducted Splits are best suited to be housed in false ceiling where floor space is scarce. The indoor unit houses the evaporator, DIDW blower and filter in a compact powder-coated sheet metal unit, while the outdoor unit houses the compressor, the condenser and the new design propeller fan.

Water cooled ducted unit is perfectly suited for shopping malls, office complexes, service apartments, industrial airconditioning and any application with multiple tenants. It provides for independent cooling and billing in multi-tenant premises. It is aesthetically better as the outdoor unit is not exposed and the condensing unit can be mounted near IDU within the building and need not be exposed outside.

Technocon Split ACs are reliable, trouble-free and quite with the unique low noise feature. Its aesthetic and well designed inner unit and low height makes it easy to conceal, giving you the great look of central air conditioning along with higher head-room under a false ceiling.

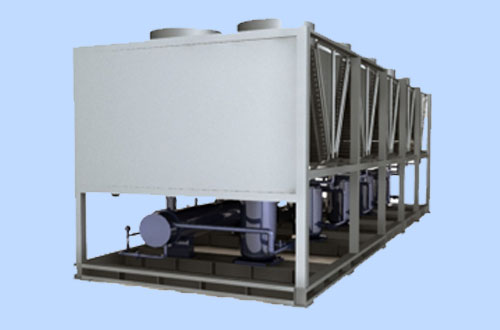

Technocon condensing units meet the cooling needs of large commercial spaces and corporate customers.These units utilise a unique modular design to deliver consistent performance over a wide operating range and ambient conditions. They are available in various models and are ideally suited to meet the cooling requirements of a wide variety of applications such as auditoriums, marriage halls, exhibition centres, textile showrooms and factory shop floors. They allow the use of various sizes of air handling units as evaporators.

Call Us

Call Us